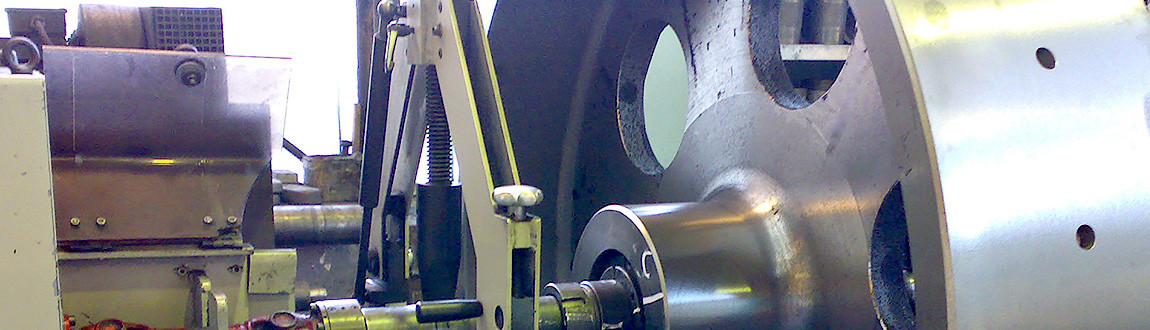

Saw band rollers

Saw band rollers for portal saws

We also produce saw band rollers for portal saws as exclusive special production or in series. All geometries can be easily produced using a flexible moulding process.

Saw band rollers are produced from batch sizes larger than 1 piece for urgently needed replacement parts , prototypes, zero-series models or series according to individual requests or drawings.

Production is also possible with alternative materials such as EN-GJS, steel, aluminum and plastic.

Downloads

Keine Einträge vorhanden

Saw band rollers are produced to the highest quality. The cast as well as the mechanical editing need to follow strict guidelines.

We take good care in balancing the pulleys. The customized varnishing is then examined for coating thickness measuring.

At a glance

- Standard material: cast iron EN-GJL-200 to EN-GJL-300 (GG-20 to GG-30) according to DIN EN 1561

- Implementation for circumferential speeds up to 42 m/s in gray cast EN-GJL-200 to EN-GJL-300

- With overloaded drives or faster circumferential speeds also custom-made products with alternative materials, i.e. spheroidal graphite iron (EN-GJS-400 to EN-GJS-700), iron cast (GS) or steel welding

- Weight optimized custom-made products also available in various aluminum materials

- Shaft-hub connections with cylindrical drill, tolerance field for press fittings, with or without feather key, preparations for the intake of couplings, flanges etc.

- Arm or base pulley designs

- Custom-made

products up to 2.500 mm in diameter

- By default saw band rollers are balanced in grade G16, G6.3 or G2.5

- Saw band rollers

- All surfaces are grounded to avoid corrosion, processed functional surfaces are conserved with spray wax / oil

- Individual surfaces and special varnishes as well as corrosion protection are possible according to individual specifications

- Upon request we offer detailed documentation to prove material properties, balancing qualities and surface treatments

The benefits

- Custom-made products according to individual customer specifications or drawings

- Pulley geometries are optimally adjusted to the corresponding drive situation

- If required full transparency due to approval drawings prior to production start or for detailed documentation

- Flexible moulding procedure without individual models and model cost

- Immediate replacement parts available in case of machine breakdown

© Copyright Lütgert & Co. GmbH | Phone: +49 52 41 / 74 07 0 | info@luetgert-antriebe.de | Índice| Aviso legal| Política de privacidad Correos electrónicos de la política de privacidad

© Copyright Lütgert & Co. GmbH

Phone: +49 52 41 / 74 07 0

info@luetgert-antriebe.de

Índice

Aviso legal

Política de privacidad

Correos electrónicos de la política de privacidad