Vibration absorbers and screen mounts

The elastic screen mounts and rubber vibration dampers are ideal for mounting and supporting screening machines and conveyor troughs. The rubber spring elements ensure almost vibration-free mounting and reliable, low-wear and long-lasting system operation.

Standard elements are used, so the components can be mounted upright or suspended. Universal joints ensure optimum damping through oscillating elements that are rotated by 90° against each other.

We offer the standardised bearing variant for free-swinging systems with maximum isolation efficiency and will be happy to advise you individually on site.

Product overview

The screen mount type CH is the universal mounting in our product range. All advantages, such as large oscillation amplitudes, high insulating effect, high power density, low residual force transmission and high resistance with regard to spontaneous loading are combined. The support of inclined screens is also possible. Transversely acting tensile forces due to belt drives are well absorbed and prevent negative, one-sided conveying.

The screen mount type CH-PL is the optimization in terms of

power density. Sufficient oscillation amplitudes, good insulating effect

and good resistance with regard to spontaneous loading are retained.

The support of inclined screens is also possible. If a belt drive is

intended to drive the unbalance shafts, we recommend the use of a motor

base

(e.g. Motor base MW8).

The screen mount type CH-HL enables the mounting of hanging screens. All advantages, such as large oscillation amplitudes, high insulating effect, high power density, low residual force transmission, high resistance with regard to spontaneous feeding are combined. Also inclined screens are also possible. Transversely acting tensile forces due to belt drives are well absorbed and prevent negative one-sided conveying. Although the screen mounting type CH-HL is tear- and break-proof, the CE guidelines must be taken into account for hanging installations..

The screen mount type CS is the optimization with regard to the overall height. Reduced vibration amplitudes and good insulating effect are maintained. Specific for the mounting of horizontally standing conveyors (linear conveyors) with mostly smaller oscillation amplitudes. The design, which is different from the CH series, results in a detuning in the natural frequency of the mounts. Thus, the screen mounting type CS can also be used as a support between the foundation and a counter-swinging frame in combination with our mountings type CH and CH PL between the counter-swinging frame and the swinging screen.

The screen mount type CH-V19 is the further developed universal support of size 8 and offers decisive advantages such as large swing ranges, a high insulating effect and power density, low residual force transmission and high resistance. The screen support has also been enhanced with the following features: material savings, weight reduction, lower maintenance, higher corrosion resistance.

This made it possible to fulfil the desire for more compact elements with a longer service life and lower maintenance.

The screen mount type CH-I is the INOX version of the CH types and is mainly used in sizes 3 and 4 in the food and pharmaceutical industries. All advantages, such as large oscillation amplitudes, high insulating effect, high power density, low residual force transmission and high resistance with regard to spontaneous loading are combined. The support of inclined screens is also possible. Transversely acting tensile forces due to belt drives are well absorbed and prevent negative, one-sided conveying.

This vibration absorber type RD is designed to absorb tensile, shear and

pressure loads. In addition, this type is a tear-resistant mounting

for hanging loads, such as crane tracks. Therefore, it is also ideal for

ceiling and wall installations. We offer 5 sizes for application from

580 N –13.000 N per unit. The natural frequency of the elements is 9 – 27 H

depending on the size. They are mostly used for subcritical mounting

applications. (Natural frequency machine < natural frequency type

RD). If subcritical bearing arrangements are present, a damper of solid

construction with low deflection is usually selected. This dampens

shocks and impacts from slow-running machines such as punches, crushers

and mixers. With this type of mounting, the isolating effect cannot be

calculated. This must be determined by before/after tests.

The vibration absorber type VD are mainly suitable for supercritical isolation. The large spring travel results in a soft bearing and thus a small natural frequency. The excitation frequency can be up to 50Hz depending on the amplitude. The frequency ratio of the natural frequency to the excitation frequency should be at least 1:1.4. The vibration damper can be loaded in tensile, pressure and shear.

The screen mount type CE enables the mounting of hanging and standing free-oscillating machines, as well as standing plansifter machines with eccentric forced motion control. The pairing of two elements in one support allows a circular and plane oscillating movement. The screen mount type CE acts as a wear-resistant screen mount and is also able to prevent the screen box from rotating during the start-up and run-down phases. Although the screen mount type CE is resistant to tearing and breakage, the CE guidelines for hanging systems must be observed.

Your advantages

- Durable and maintenance-free operation

- Vibration-damping bearings

- Corrosion-resistant components

Areas of application

- All types of vibrating machines and conveyor chutes

- Sorting chutes in piece goods processing

- Ore dewatering screens for stone and earth (mines)

- Screening machine support for plansifters

- Vibrating conveyor transport with slider-crank drive

- Support for screening troughs

- Storage of circular and linear vibrating screens

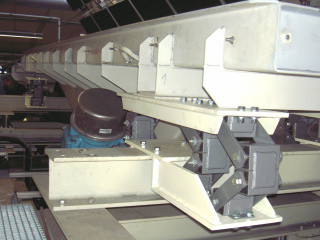

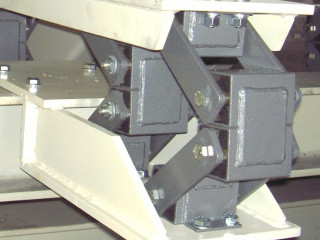

Application examples for vibration dampers and screen bearings

RESATEC screen mounts

Oscillating components for mounting a mobile vibrating screen

Oscillating components for mounting a vibrating screen

Oscillating components application in a screening machine

© Copyright Lütgert & Co. GmbH | Friedrichsdorfer Straße 48 | 33335 Gütersloh (Germany) | Phone: +49 52 41 / 74 07 0 info@luetgert-antriebe.de | Sitemap | Legal Notice | Privacy policy | Privacy policy E-mails

© Copyright Lütgert & Co. GmbH

Friedrichsdorfer Straße 48

33335 Gütersloh

Germany

Phone: +49 52 41 / 74 07 0

info@luetgert-antriebe.de

Sitemap

Legal Notice

Privacy policy

Privacy policy E-mails