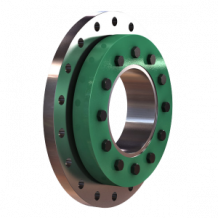

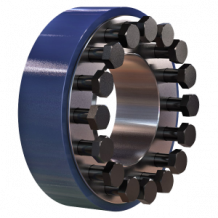

Adapter flanges

Adapter flanges / external clamping elements are used to connect disc-shaped attachments such as brake discs, pulleys and belt pulleys securely and without backlash by friction. Connection to cardan shafts is also possible a possible option.

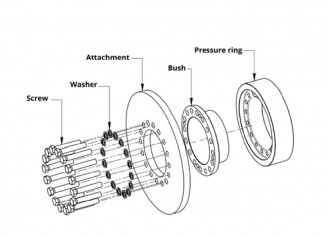

External clamping elements of "AF-12", "AF-22" and "AF-23" series consist of a conical pressure ring and a conical inner ring. The mode of operation is comparable to the 2-part shrink disc (displacement-controlled). That means, by tightening the screws, the pressure ring is pulled axially onto the inner ring. The use of tapered surfaces reduces the inner diameter of the inner part, applying radial pressure to the shaft.

Compared to 2-part shrink discs (path-controlled), mounting flanges of the "AFS", "AF-12", "AF-22" as well as "AF-23" series clamp directly onto the shaft. The clamping force applied by the outer clamping element creates a frictional connection at the contact surfaces between the inner ring and the shaft.

Downloads

Adapter flanges / Flange couplings(2865 KB)

Adapter flanges / Flange couplings(2865 KB)

The inner rings of the mounting flanges also have push-off threads due to their small cone angle. This allows safe and easy disassembly at any time. Like 2-part shrink discs (displacement-controlled), mounting flanges have a fixed displacement. This allows simplified assembly without the use of a torque wrench. Compared to other friction-locked connections, the transmittable torque of the mounting flanges is not defined only by the applied pressure of the conical functional surfaces.

Due to the design of the mounting flanges, the connecting screws also have a considerable influence on the torque to be transmitted. One reason for this is that, compared with other external clamping elements, mounting flanges are in the force flow. The transmittable forces are therefore transmitted from the mounting part through the external clamping element to the shaft and back again. Therefore, the design of the bolted connection must be taken into special consideration in the case of mounting flanges.

The benefits

- High transmittable torques with short installation length

- Transmission of dynamic loads

- Transmittable torque from 20 Nm to 426.000 Nm

- Shaft diameter from 11 mm to 1000 mm

- Short assembly times and cost advantages compared to flange couplings

- Easy disassembly

Product overview

Mounting flanges / external clamping elements of the series "AF-12", "AF-22" and "AF-23" are manufactured in these designs:

- Design A: with thread in the outer ring

- Design AB: with thread in the outer ring and centering

- Design C: with thread in the mounting part

- Design BC: with thread in the mounting part and centering

Assembly

The mounting flange is supplied ready for installation. Power is transmitted via pressure and friction between the contact surfaces of the mounting flange, shaft and mounting part. Special attention must therefore be paid to the controlled tightening of the clamping screws and the condition of the contact surfaces. The prescribed tolerances for the shaft and the attachment part must be observed.

The disc connector should be dismantled and cleaned after disassembly. The tapered surfaces are coated with a solid grease compound (eg. Molykote G Rapid) by the manufacturer. Recoat with Molykote G Rapid if tapered surfaces are undamaged.

Grease the threads and head bearinig surfaces of the bolts with Molykote.

Application examples

Adapter flanges are used in marine industry, conveying industry, mixing and process engineering, hydropower engineering. In addition, as far as the technical requirements allow, adapter flanges/ external clamping elements of the series "AFS", "AF-12", "AF-22" as well as "AF-23" are often chosen as a more cost-effective alternative to the use of flange couplings of the series "FK" or "FKB", as these usually have a more compact design, especially with larger shaft diameters.

© Copyright Lütgert & Co. GmbH | Friedrichsdorfer Straße 48 | 33335 Gütersloh (Germany) | Phone: +49 52 41 / 74 07 0 info@luetgert-antriebe.de | Sitemap | Legal Notice | Privacy policy | Privacy policy E-mails

© Copyright Lütgert & Co. GmbH

Friedrichsdorfer Straße 48

33335 Gütersloh

Germany

Phone: +49 52 41 / 74 07 0

info@luetgert-antriebe.de

Sitemap

Legal Notice

Privacy policy

Privacy policy E-mails